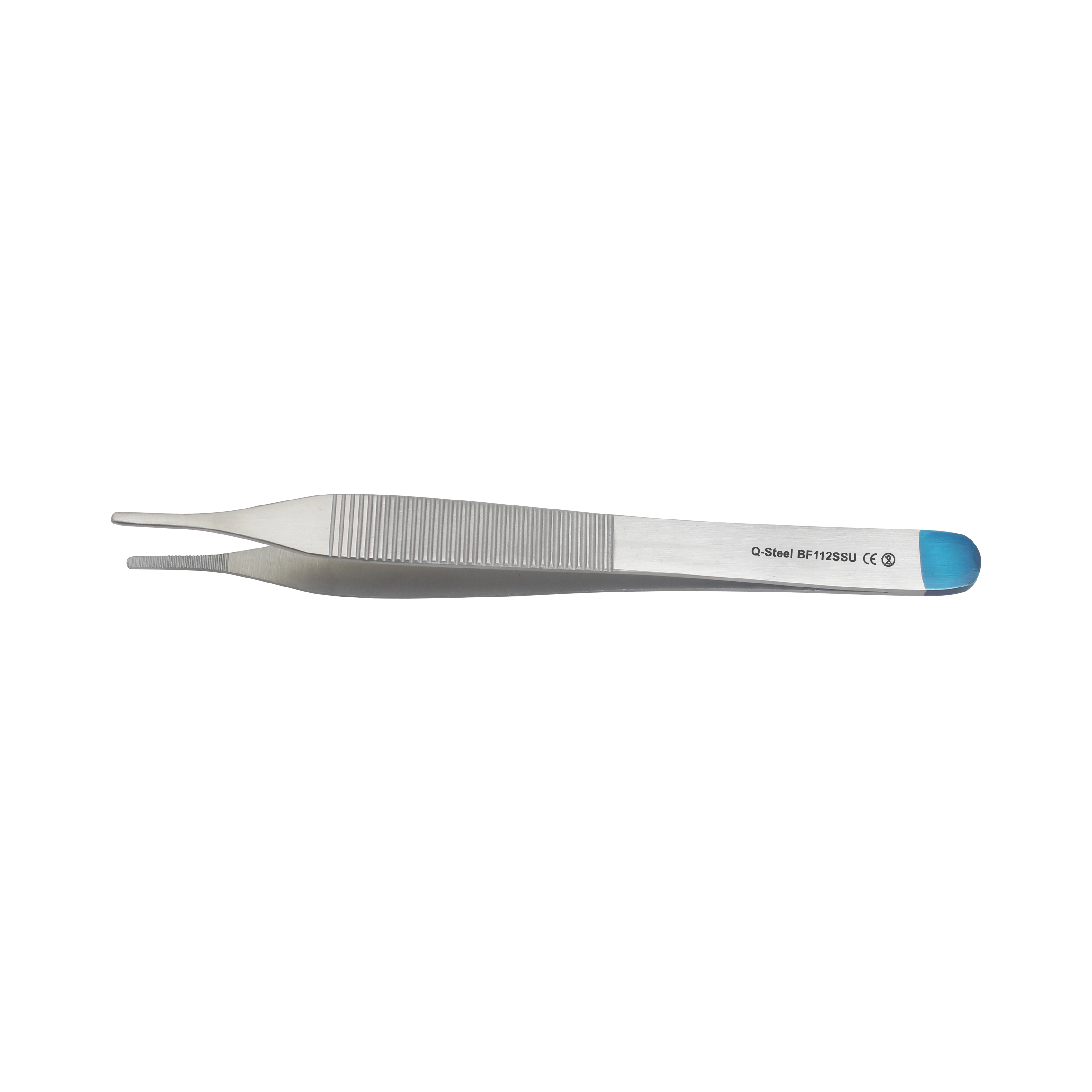

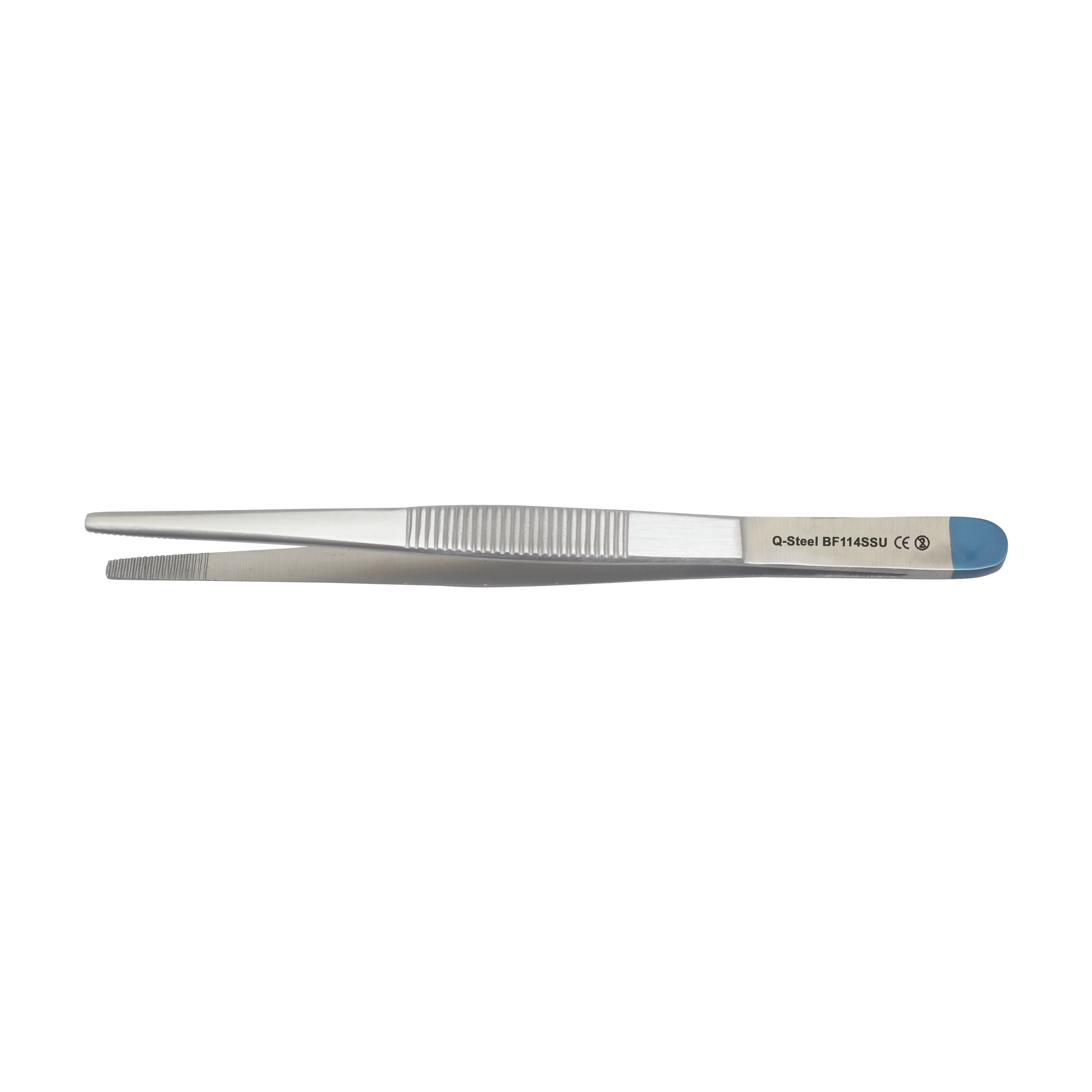

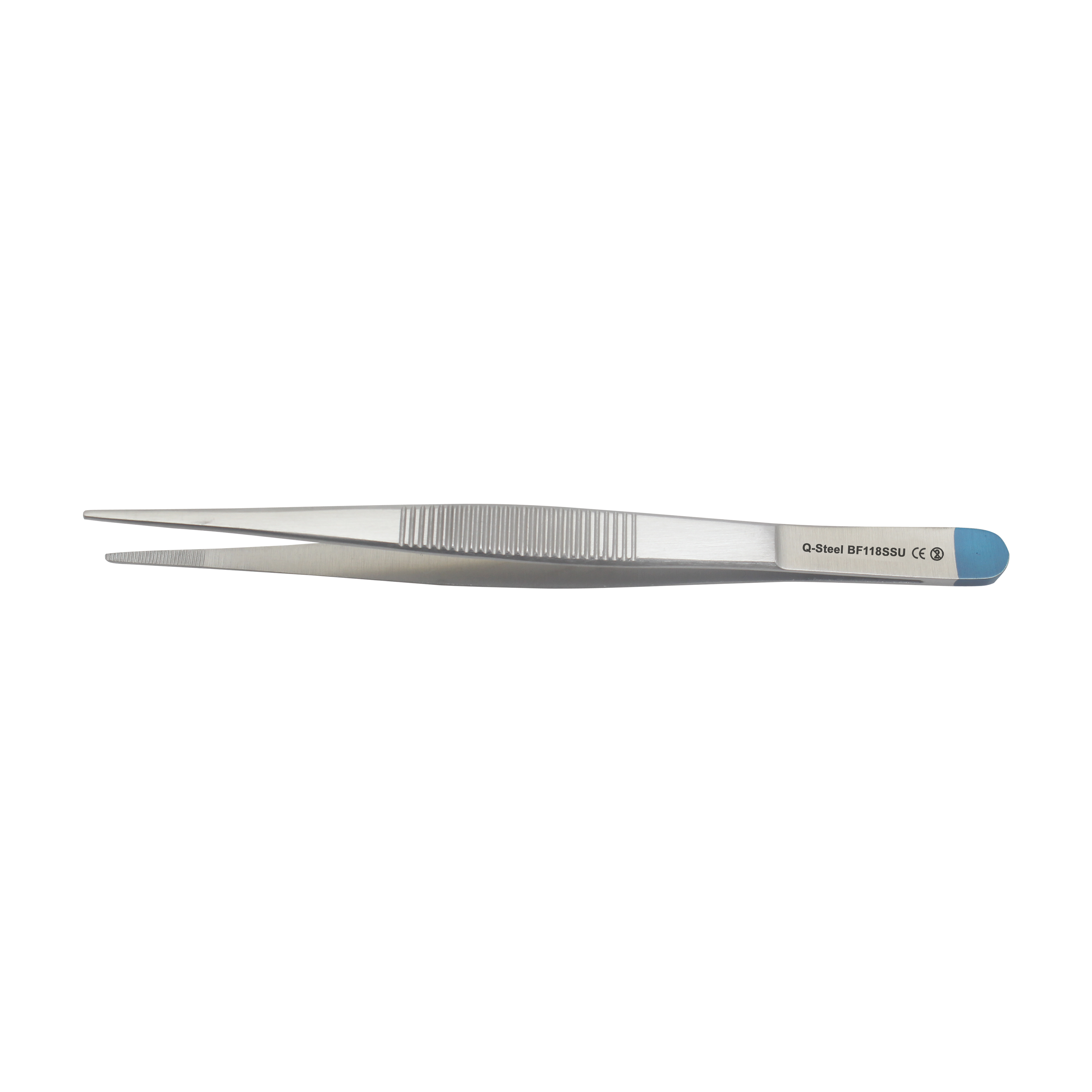

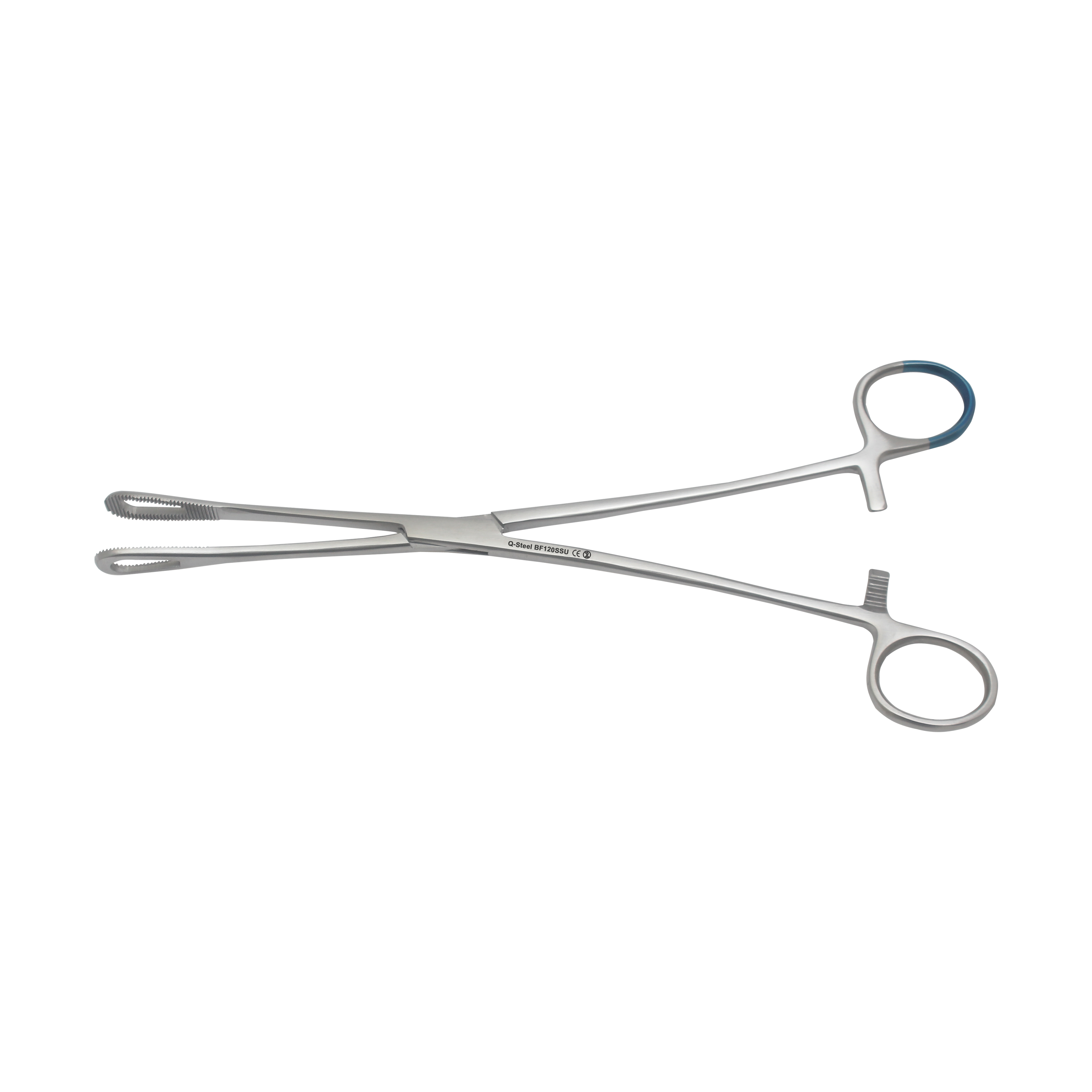

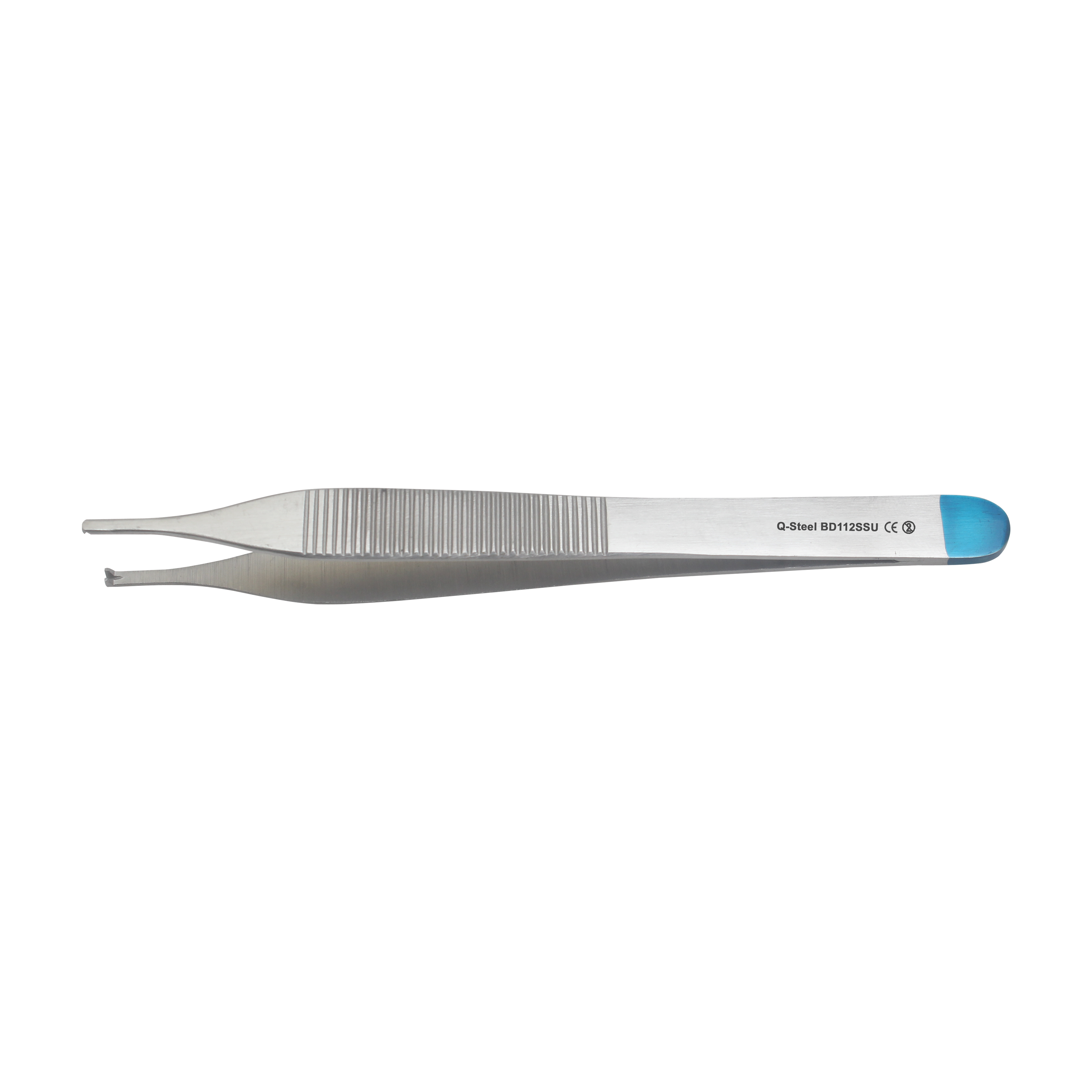

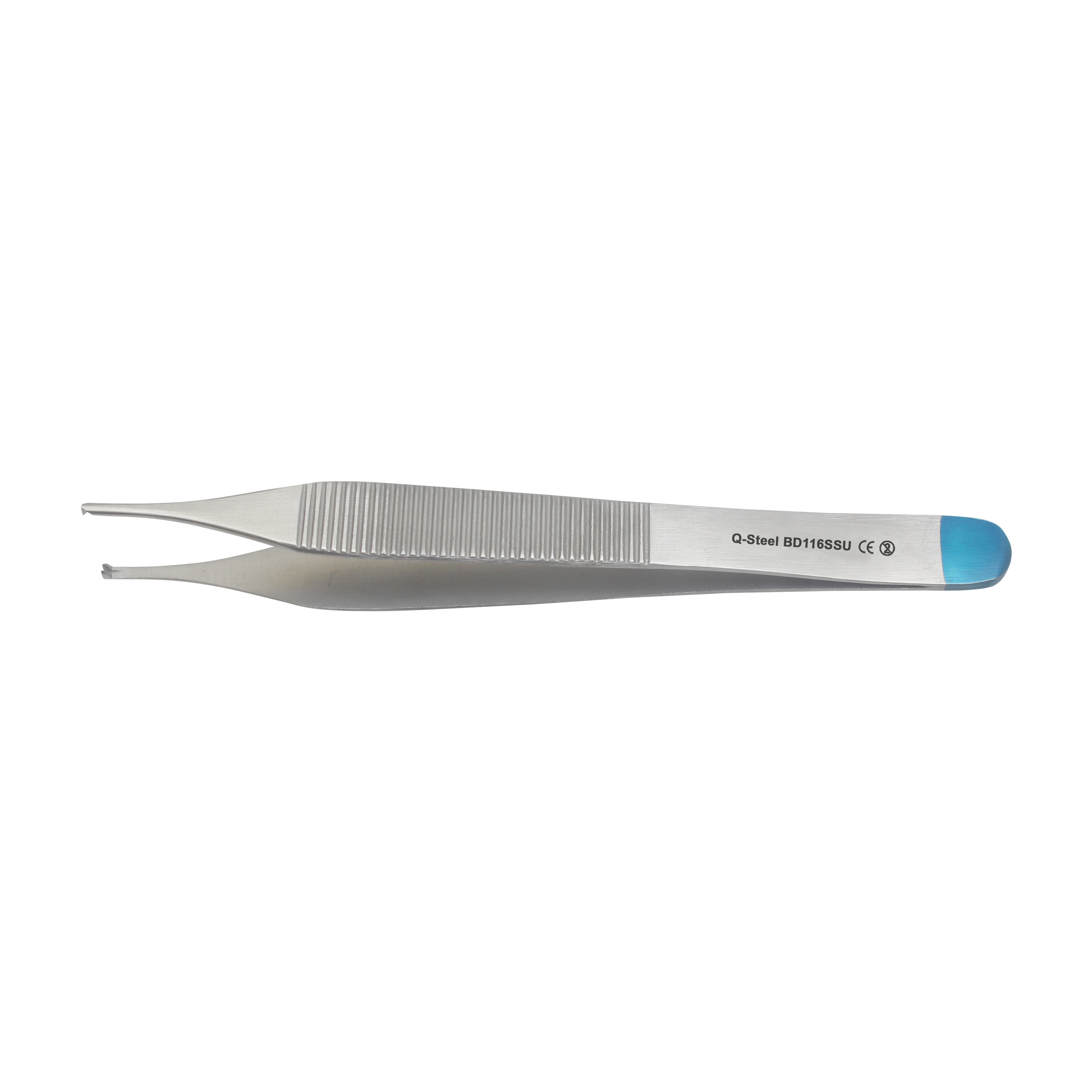

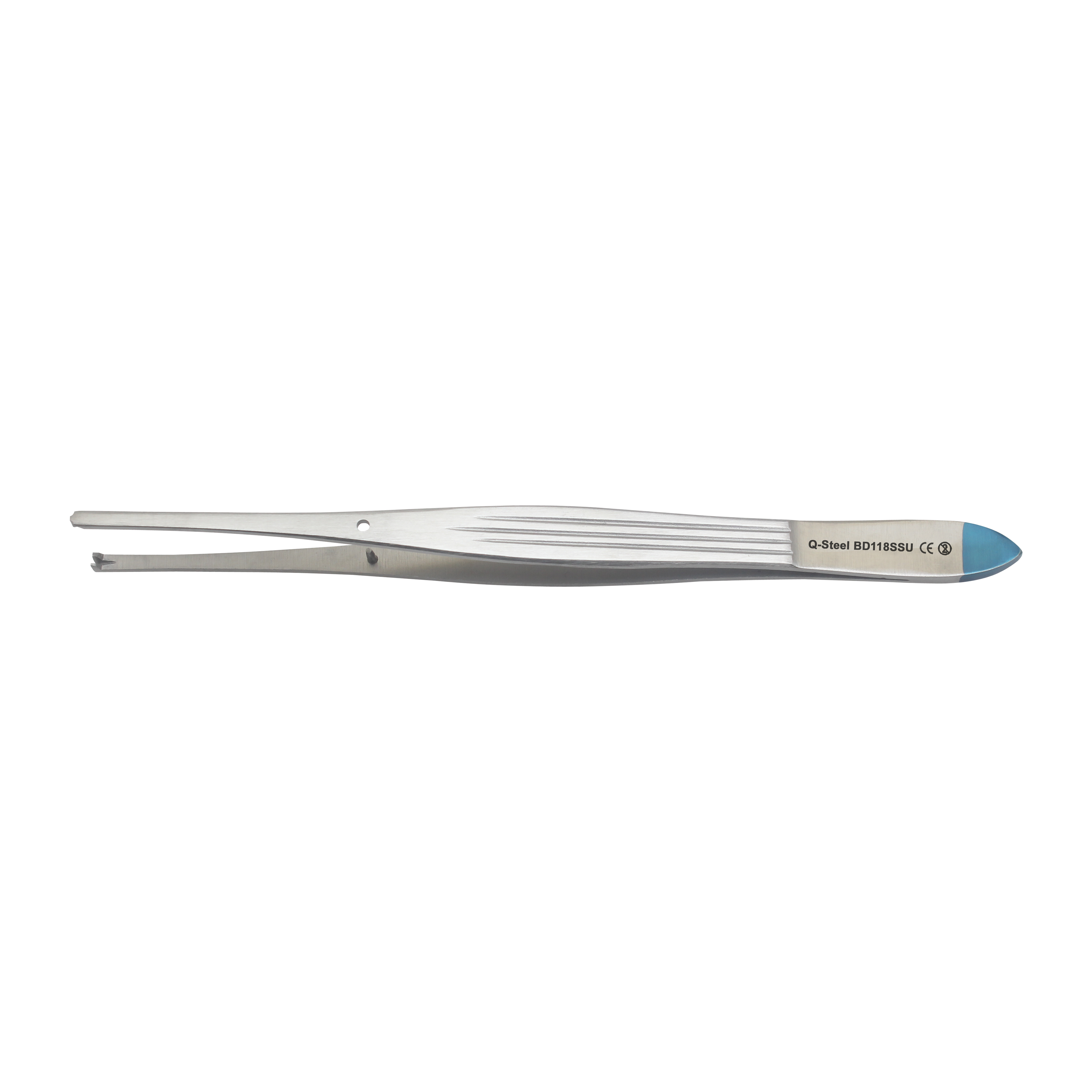

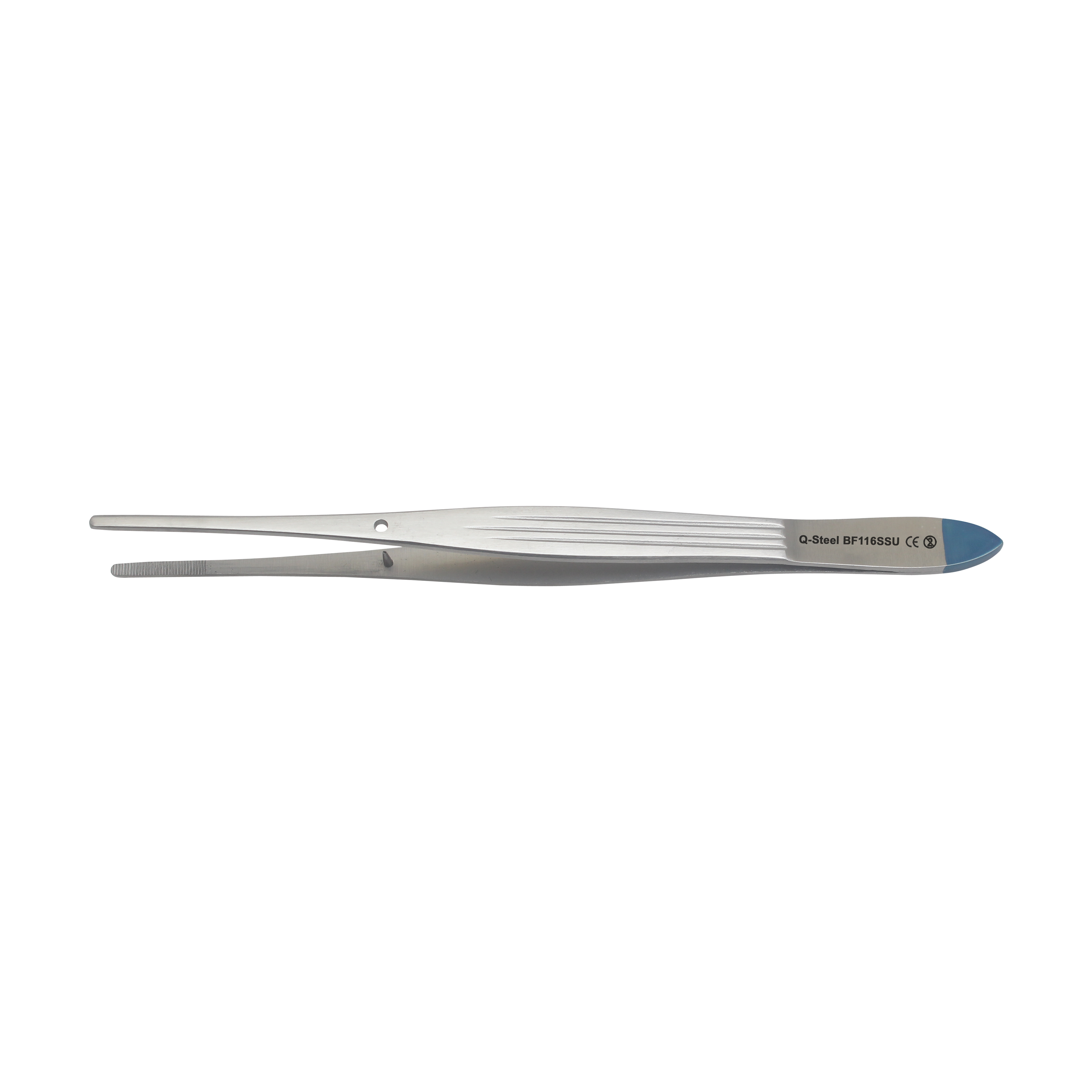

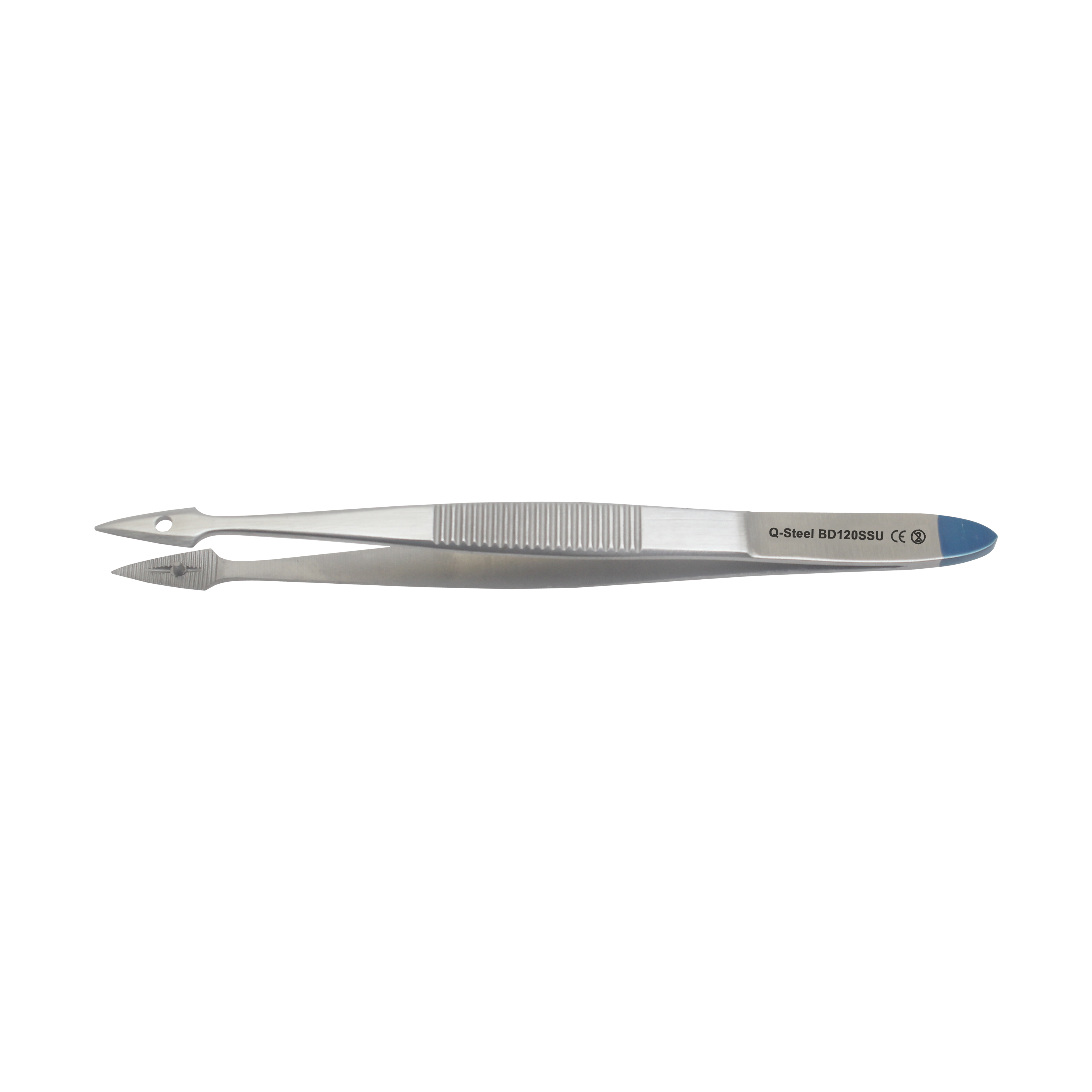

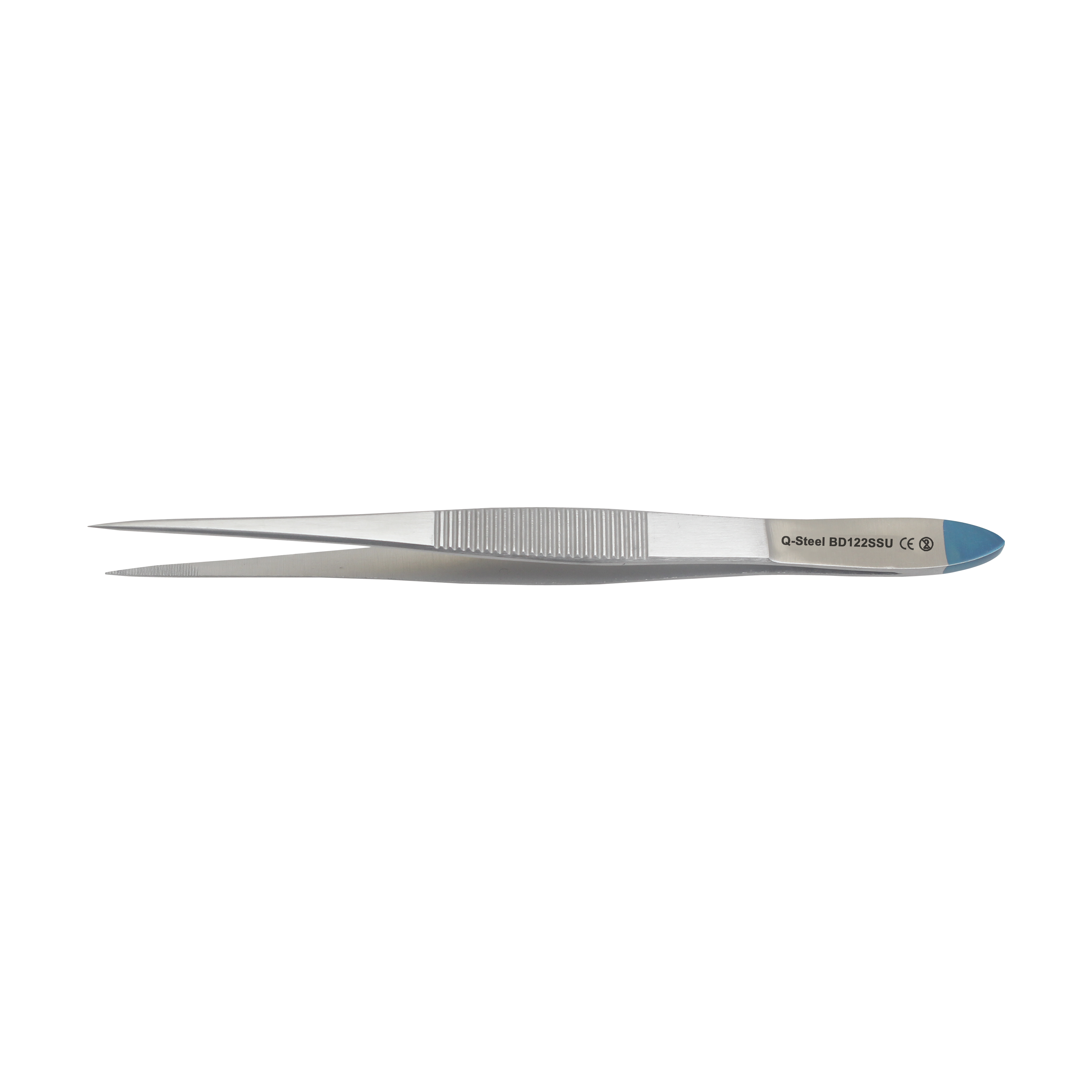

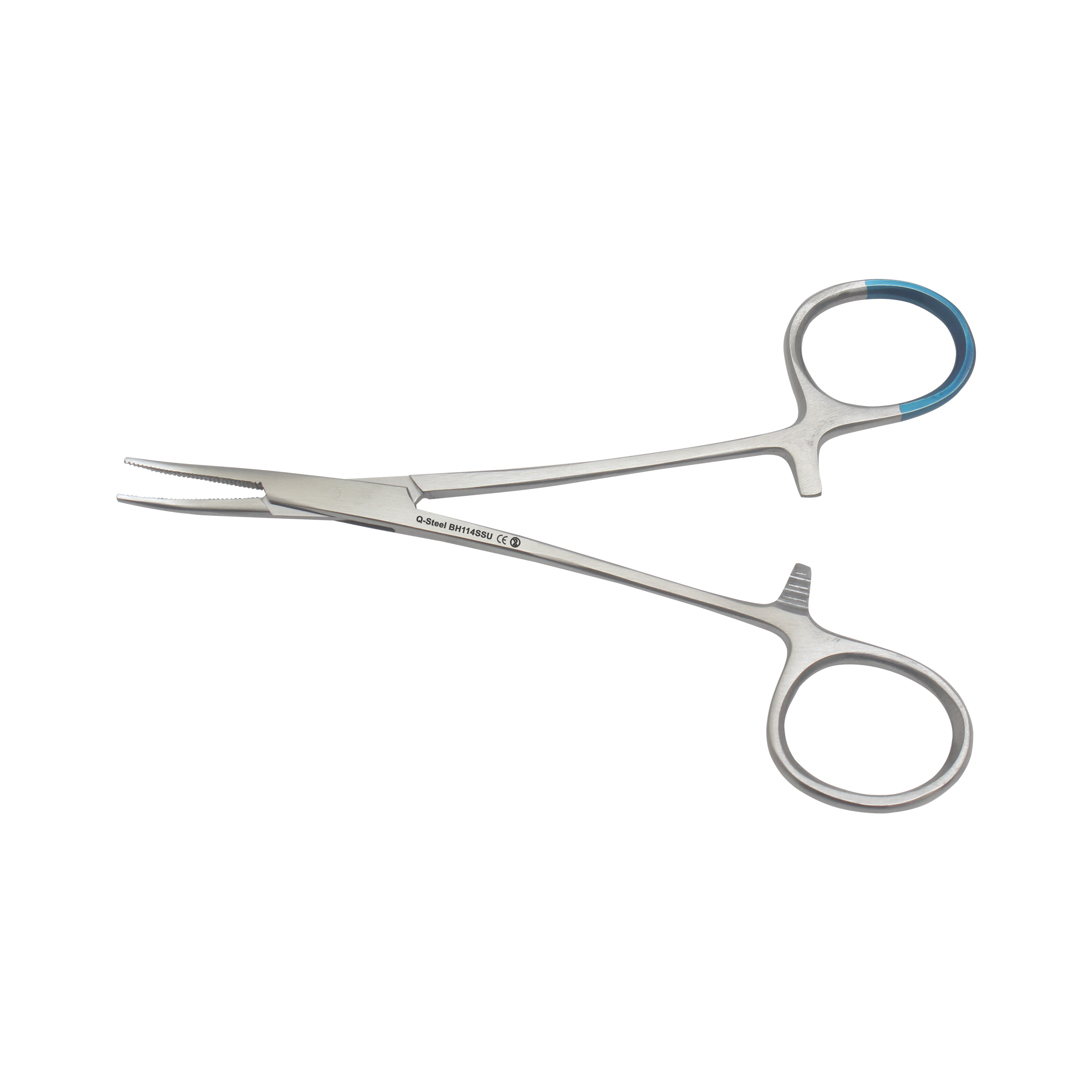

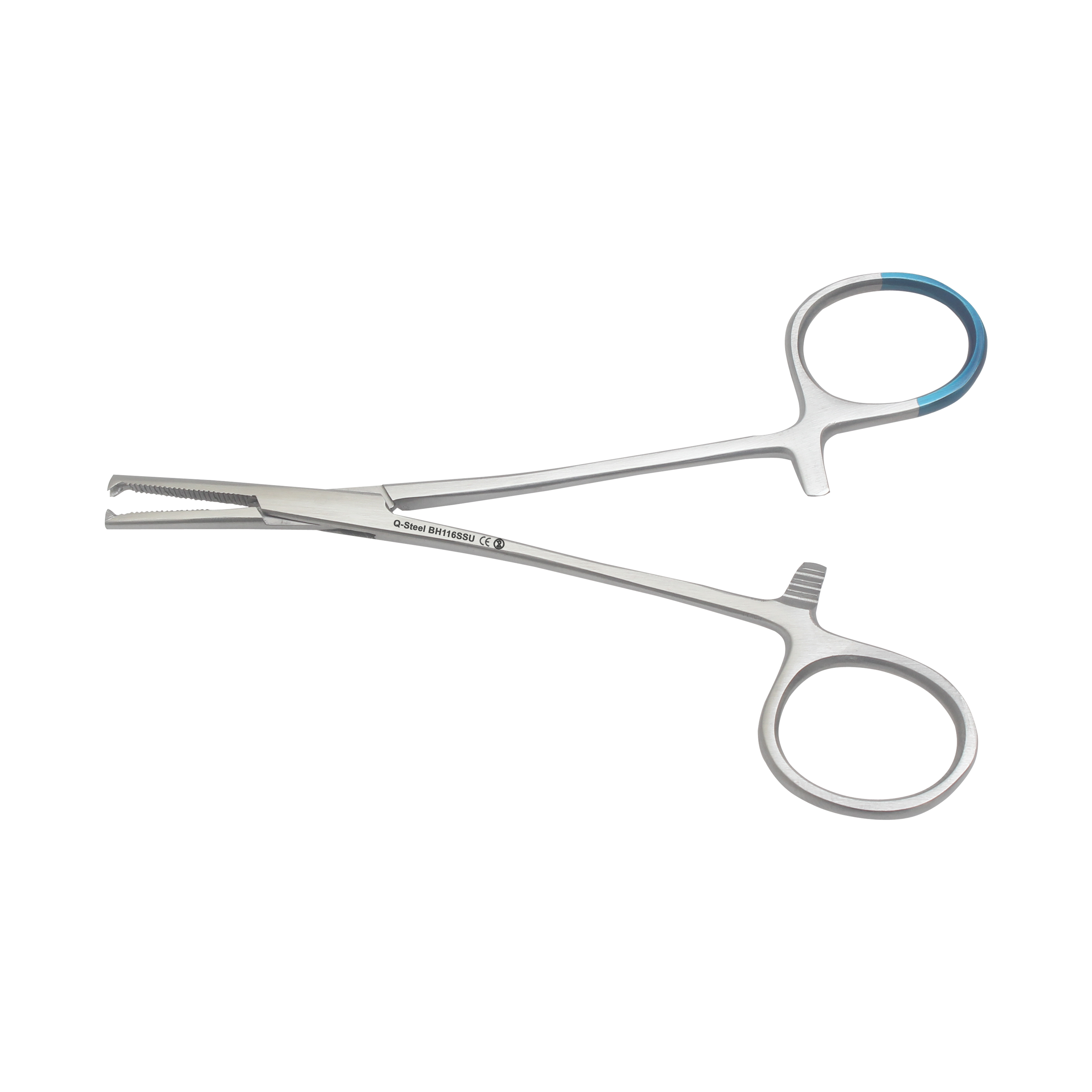

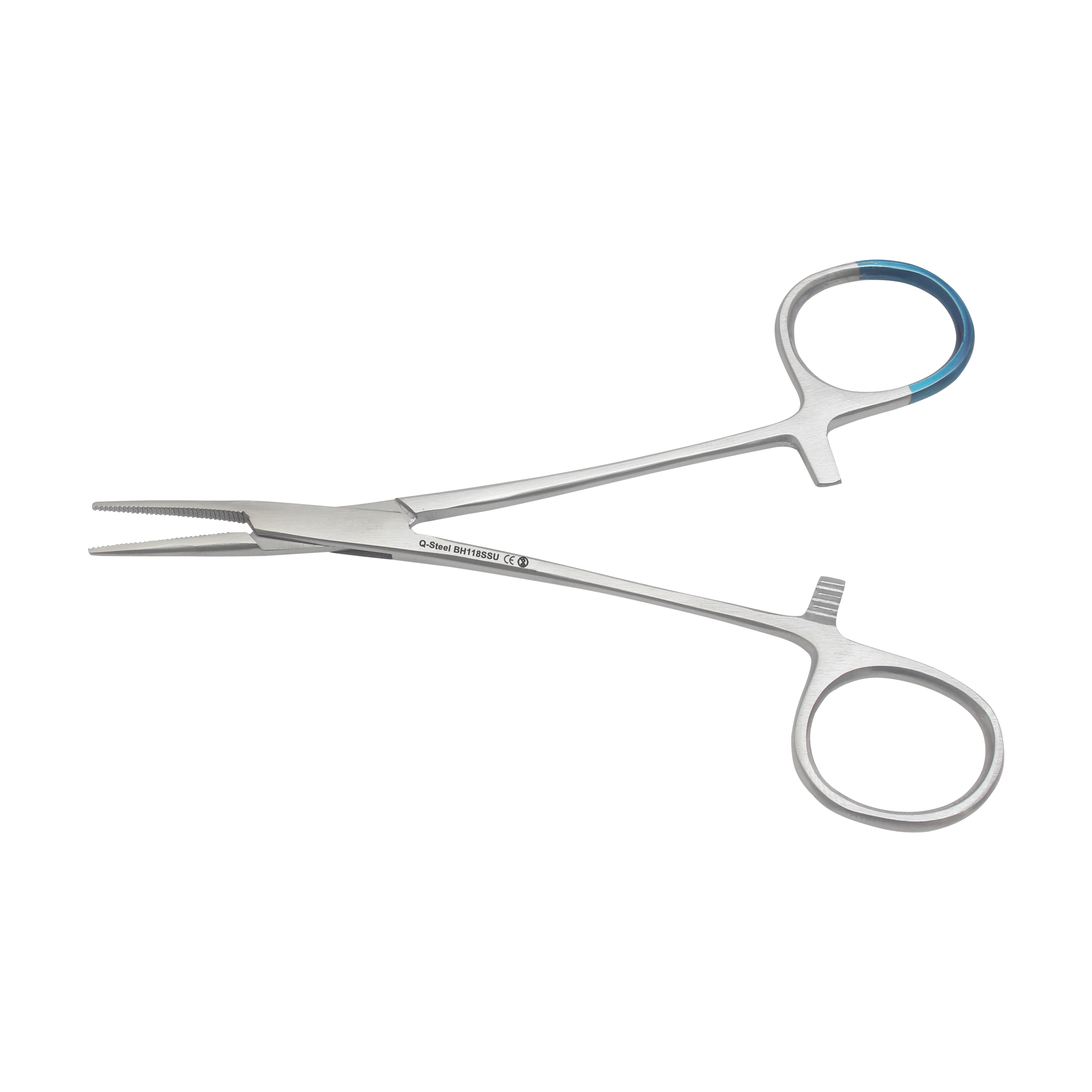

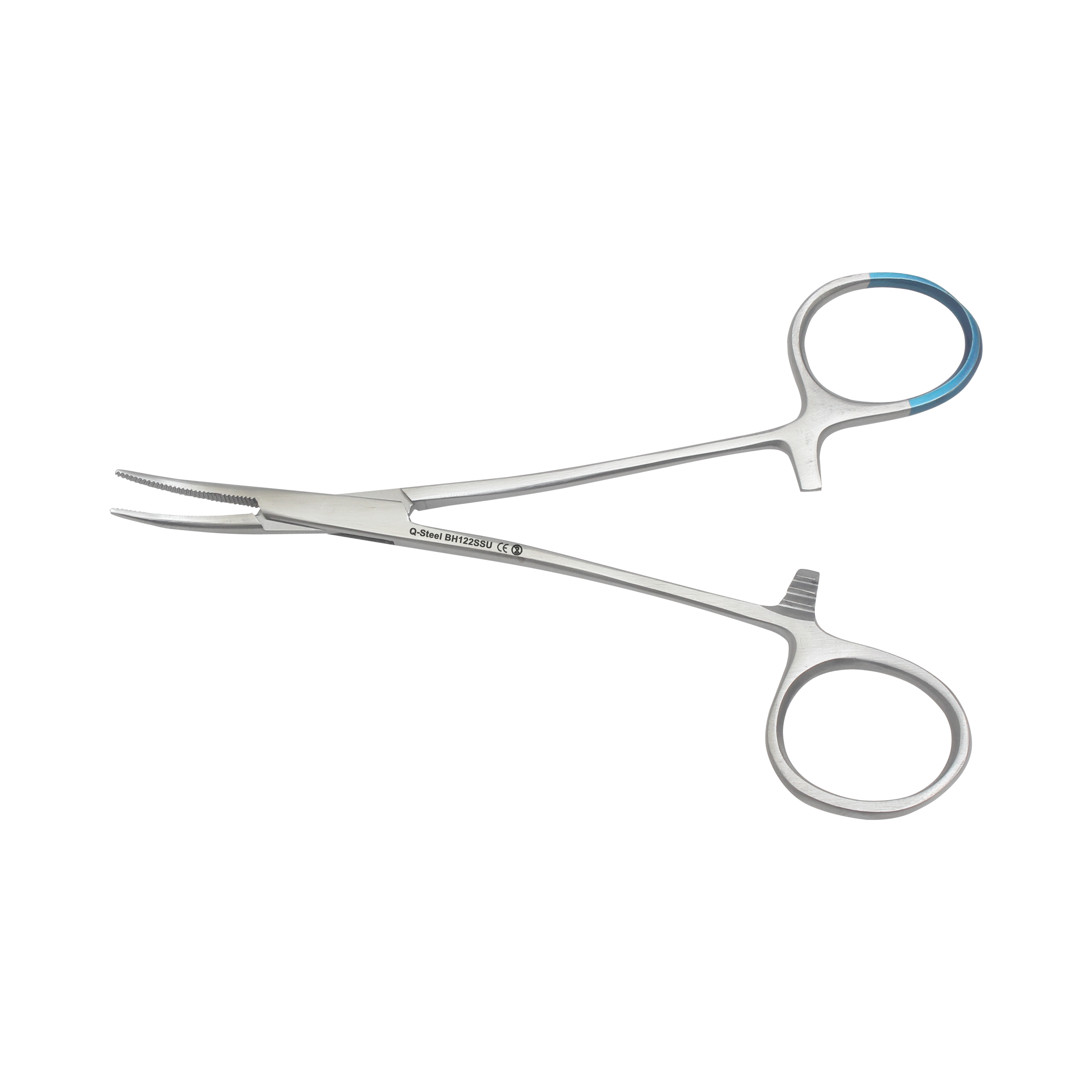

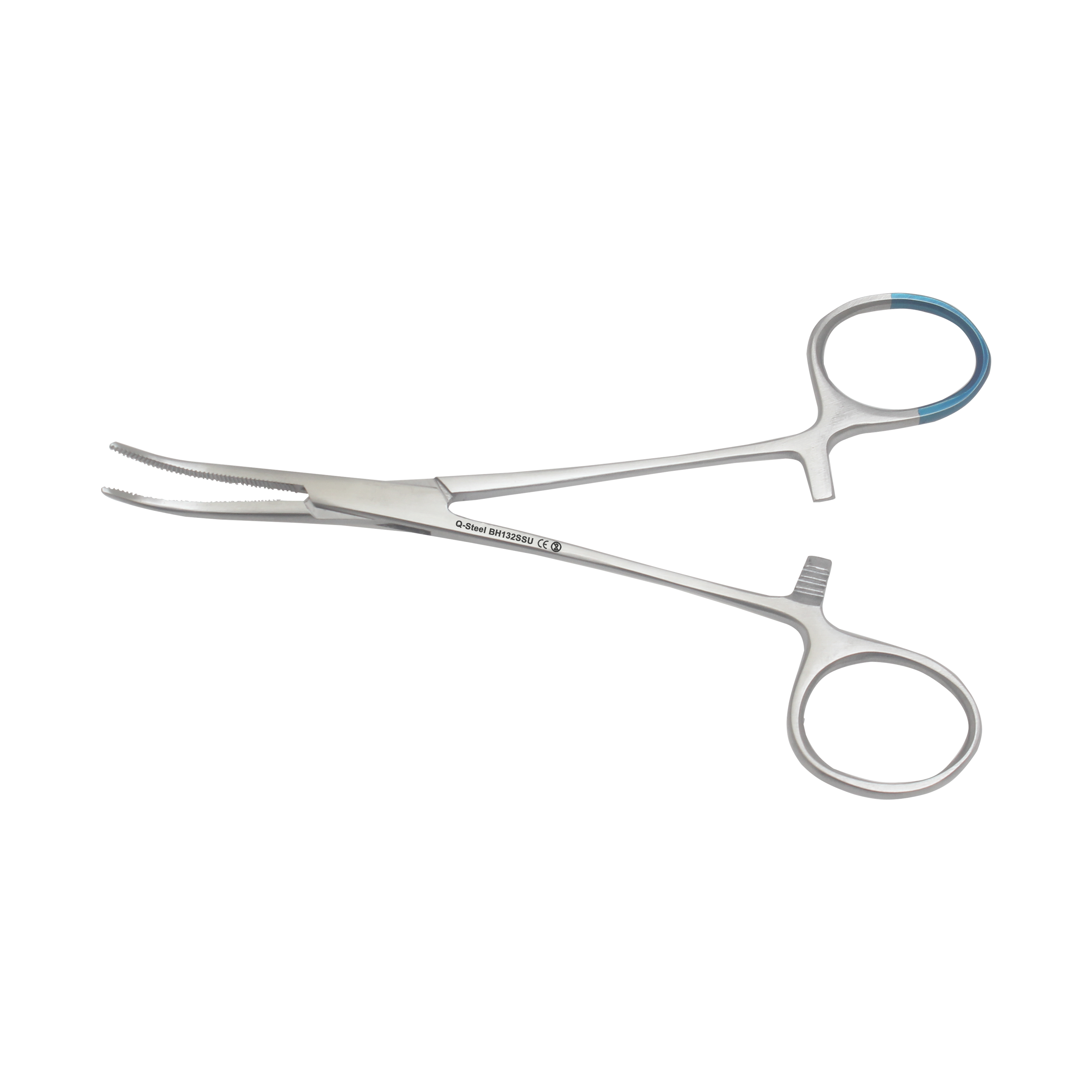

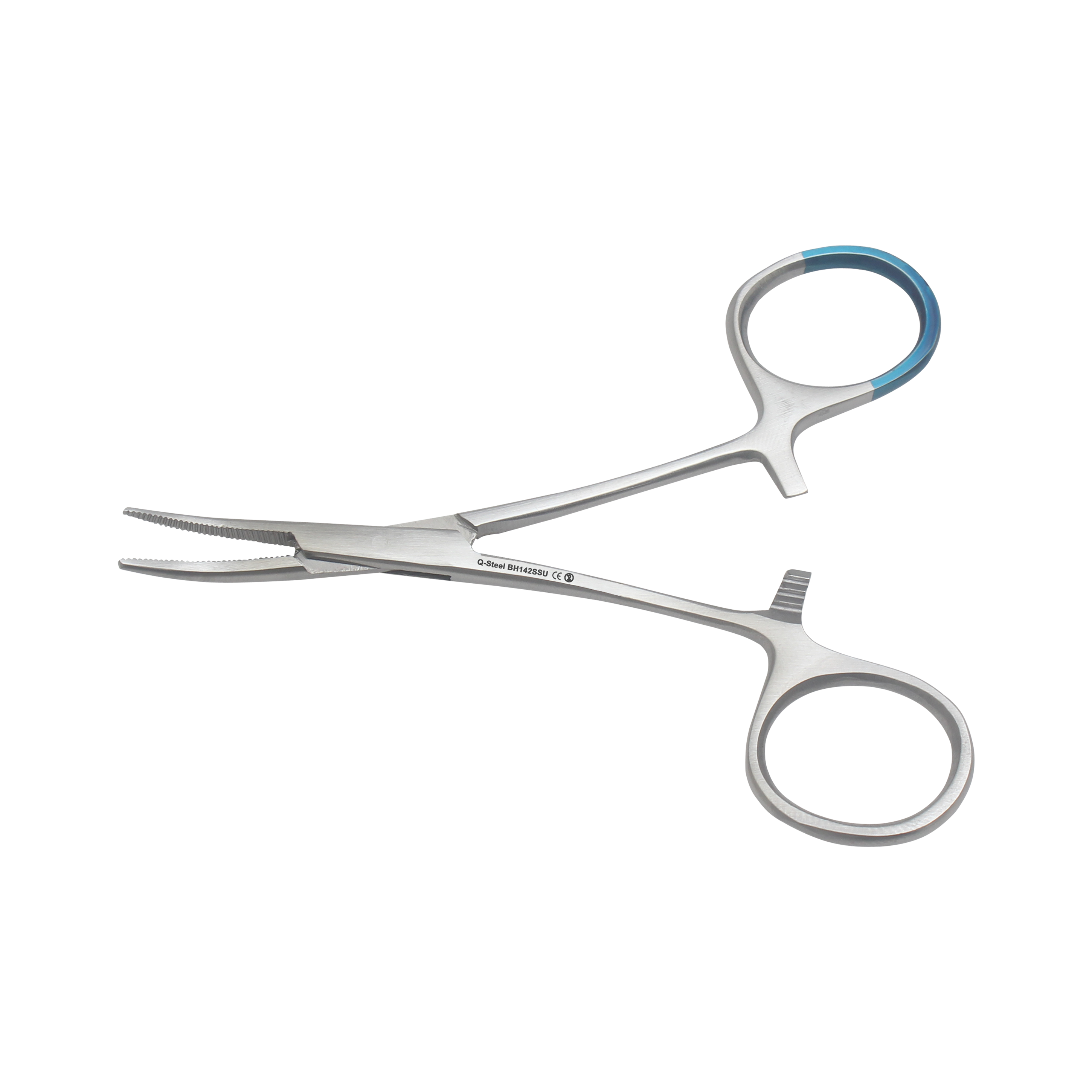

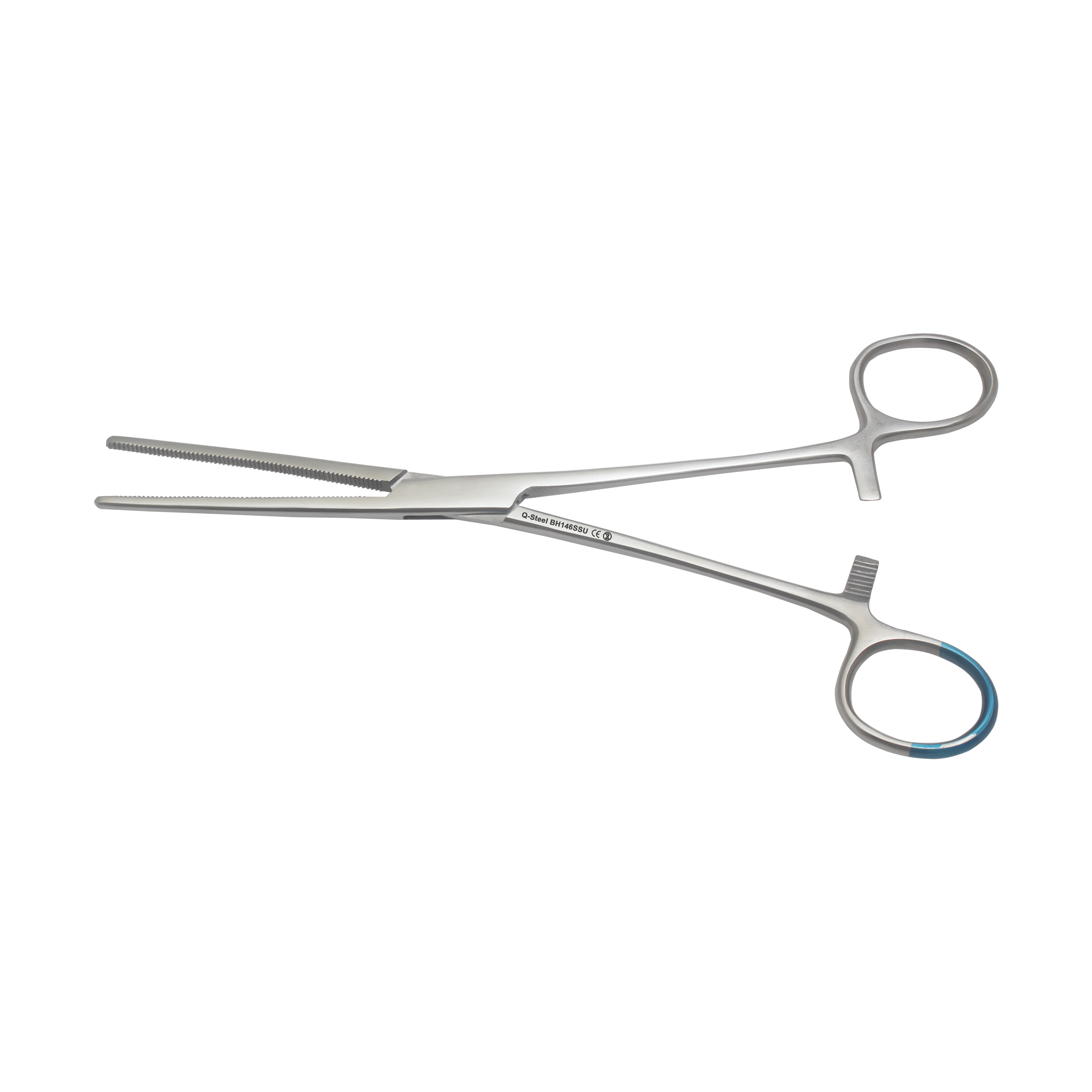

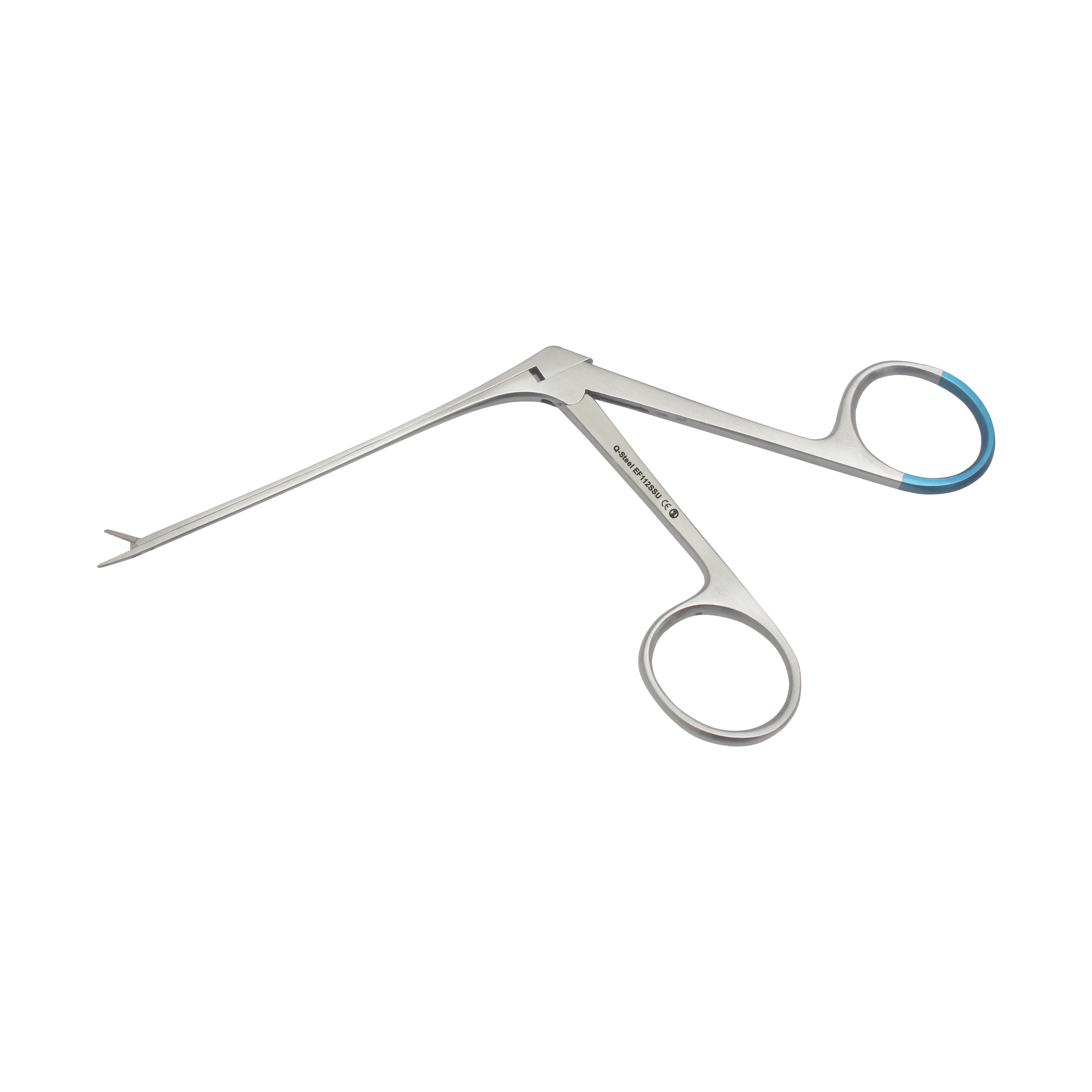

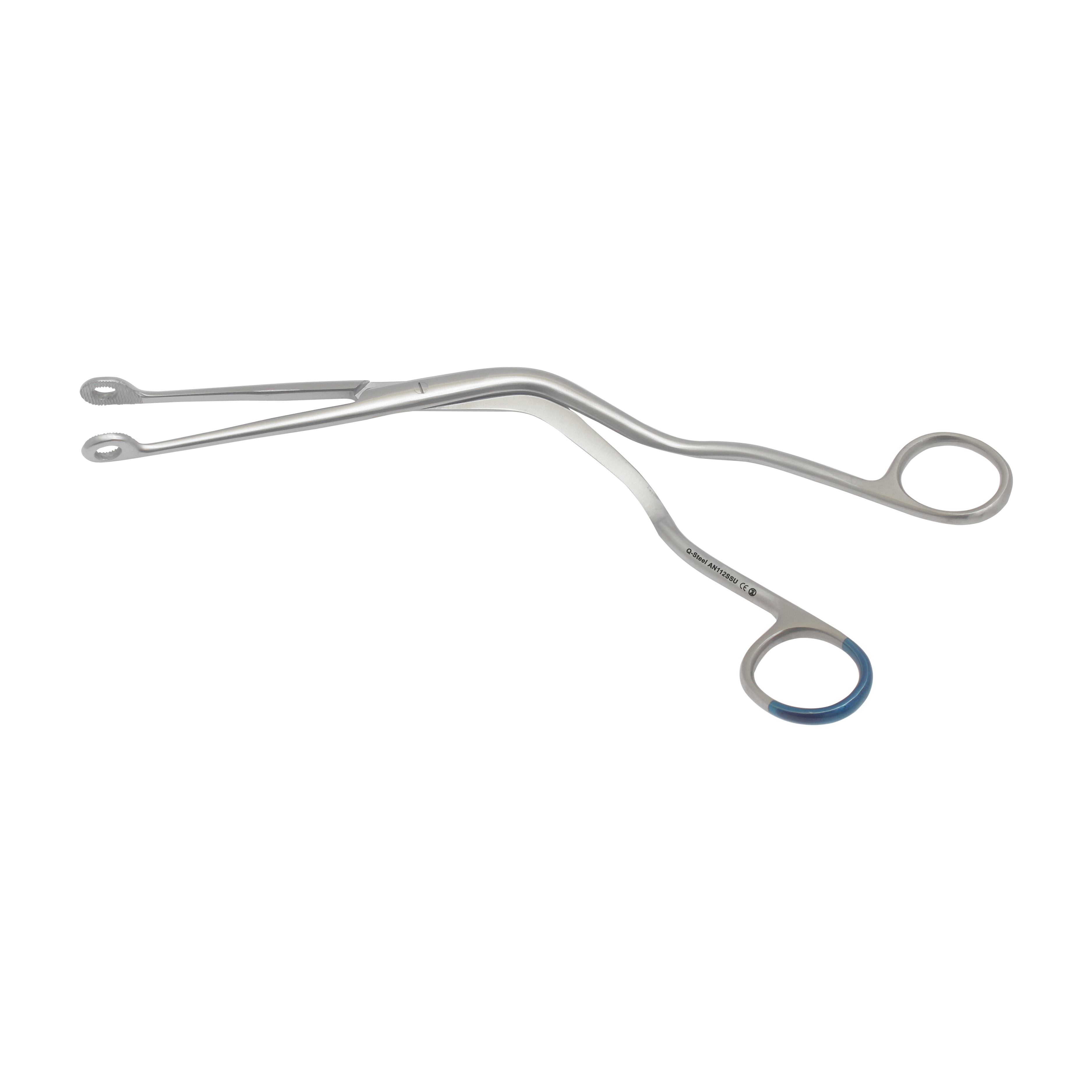

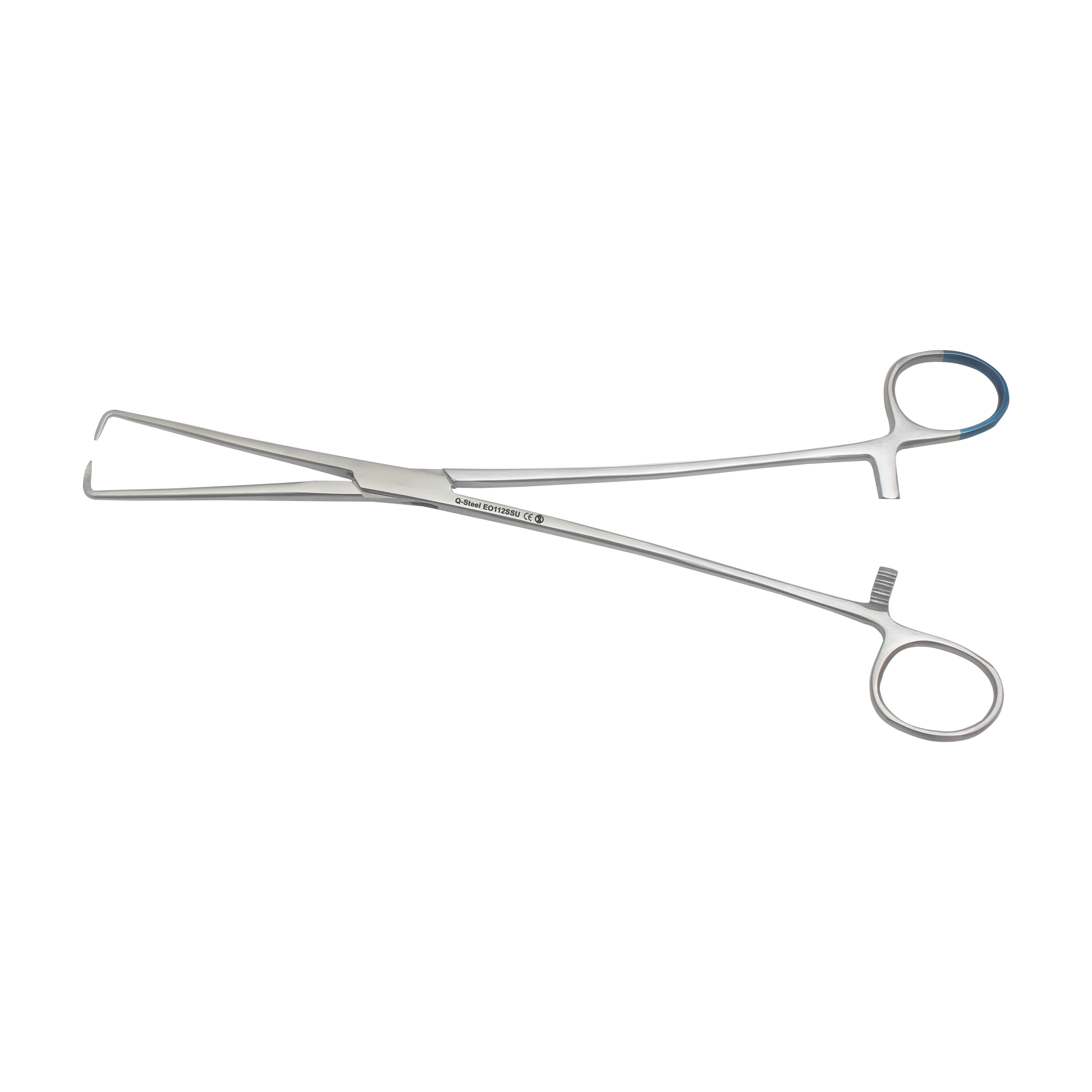

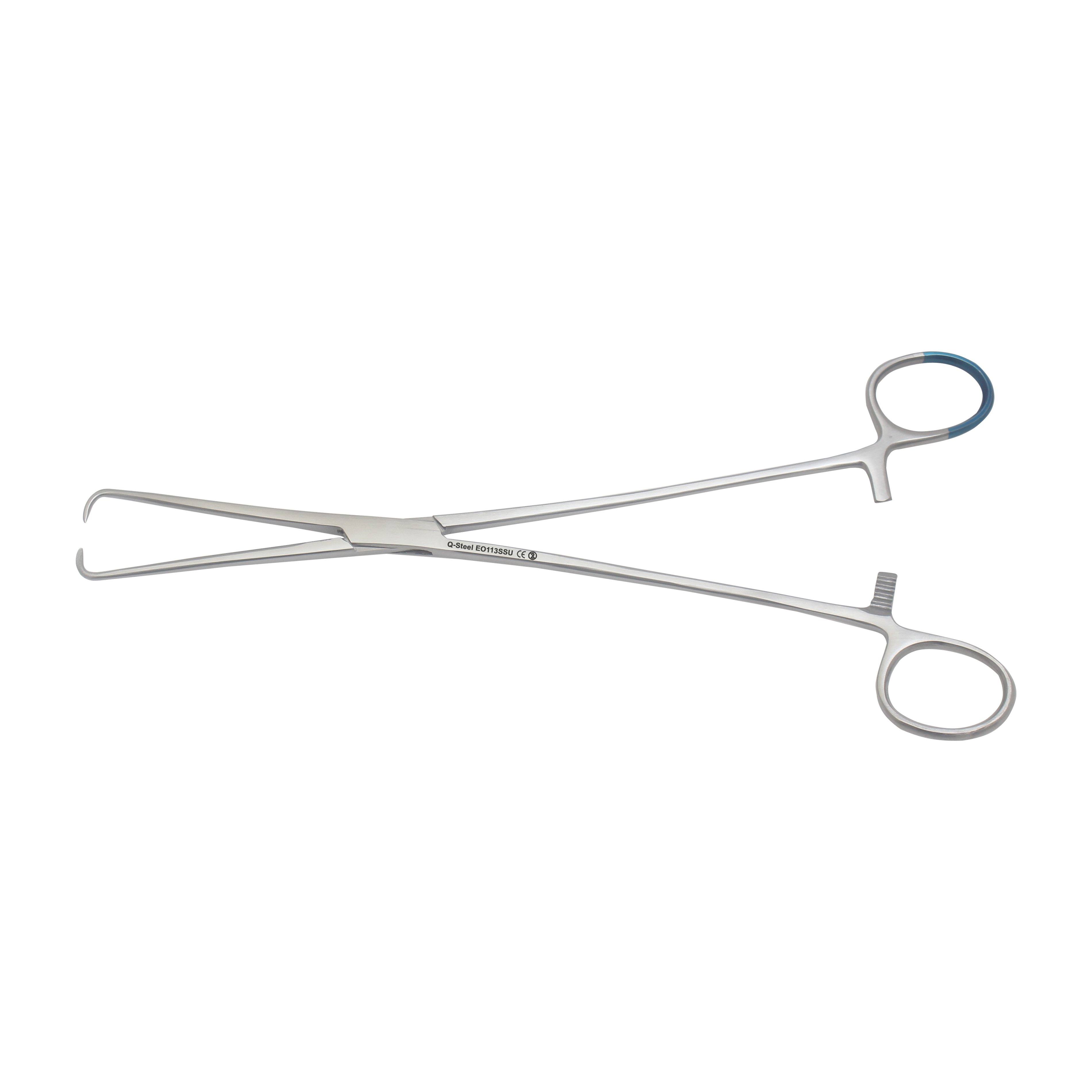

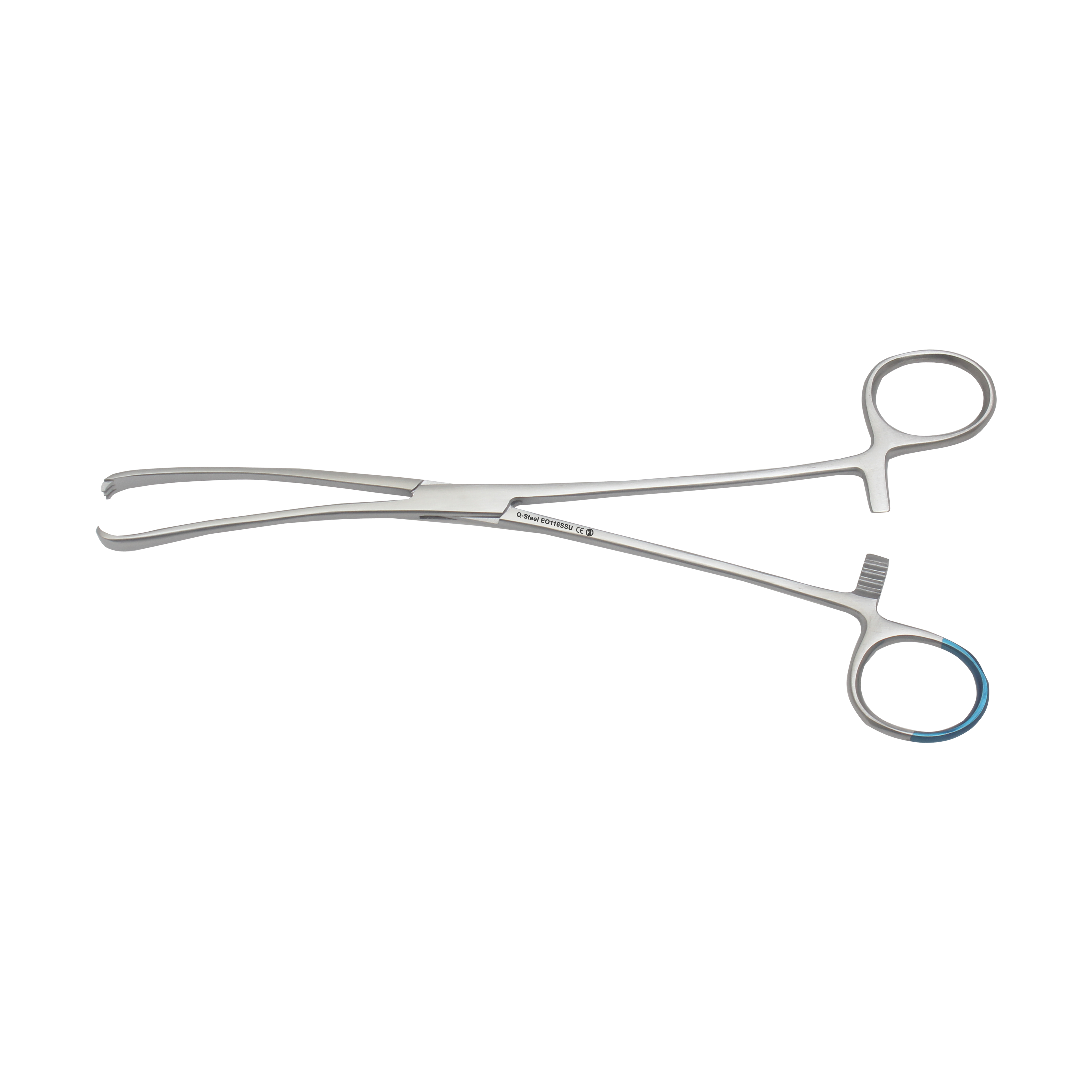

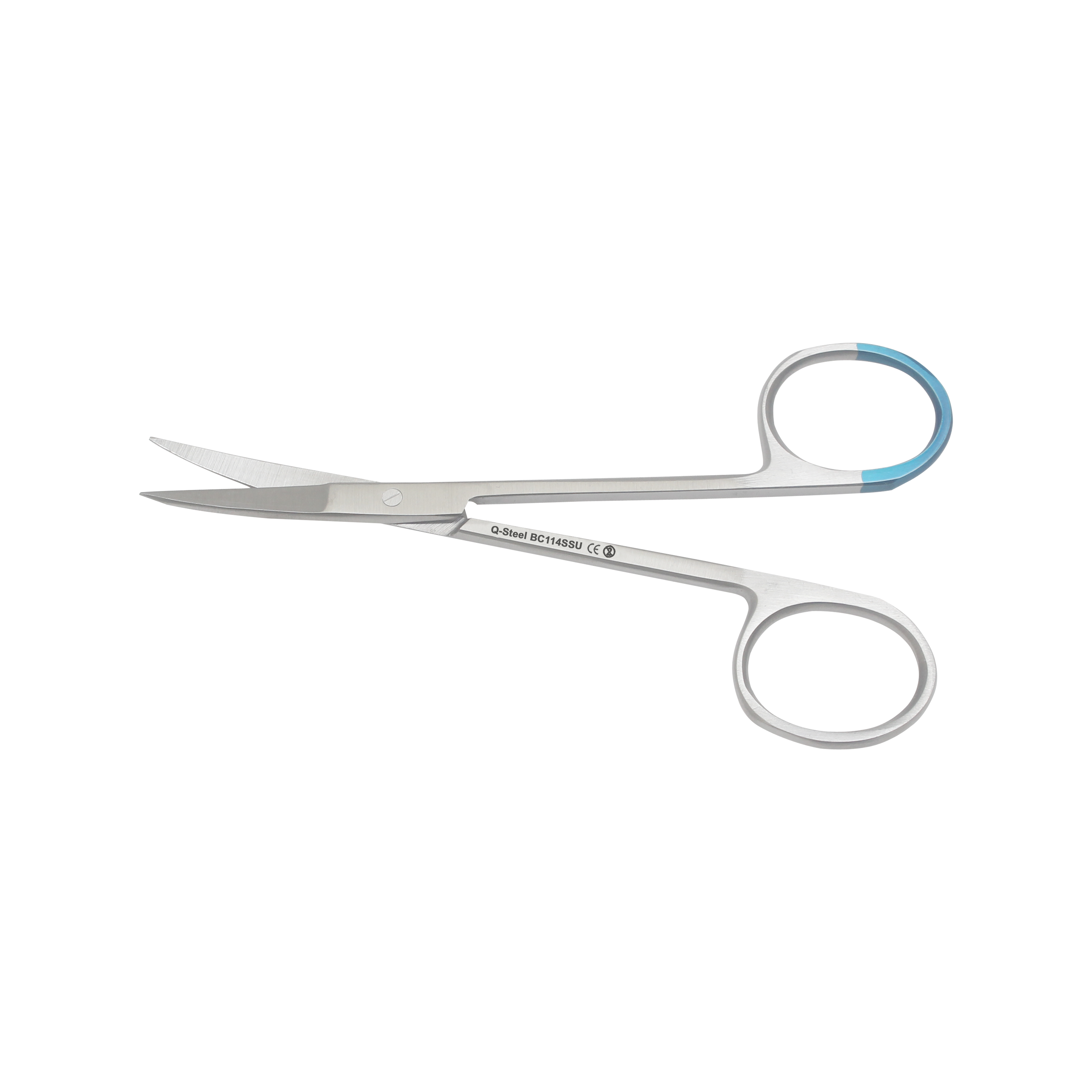

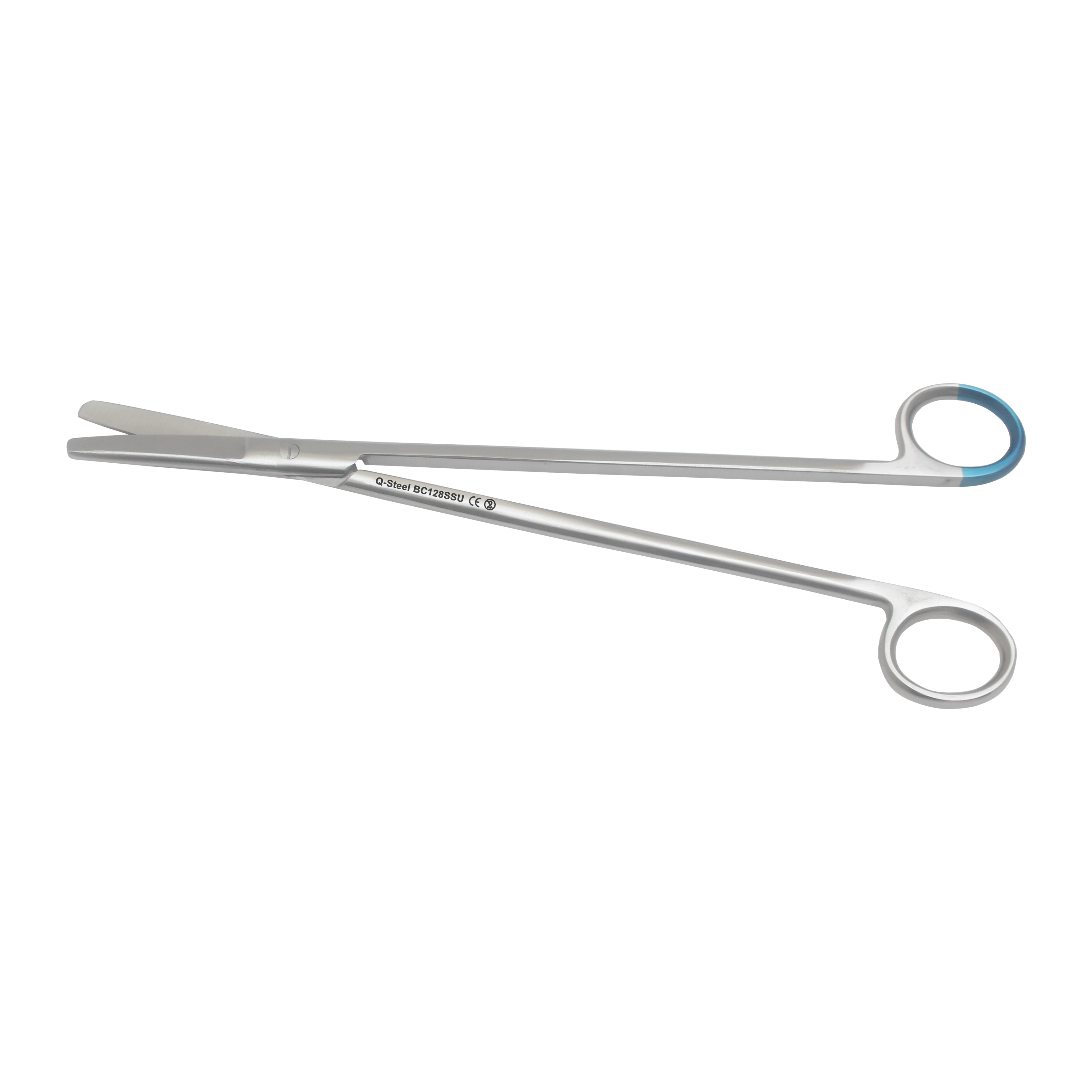

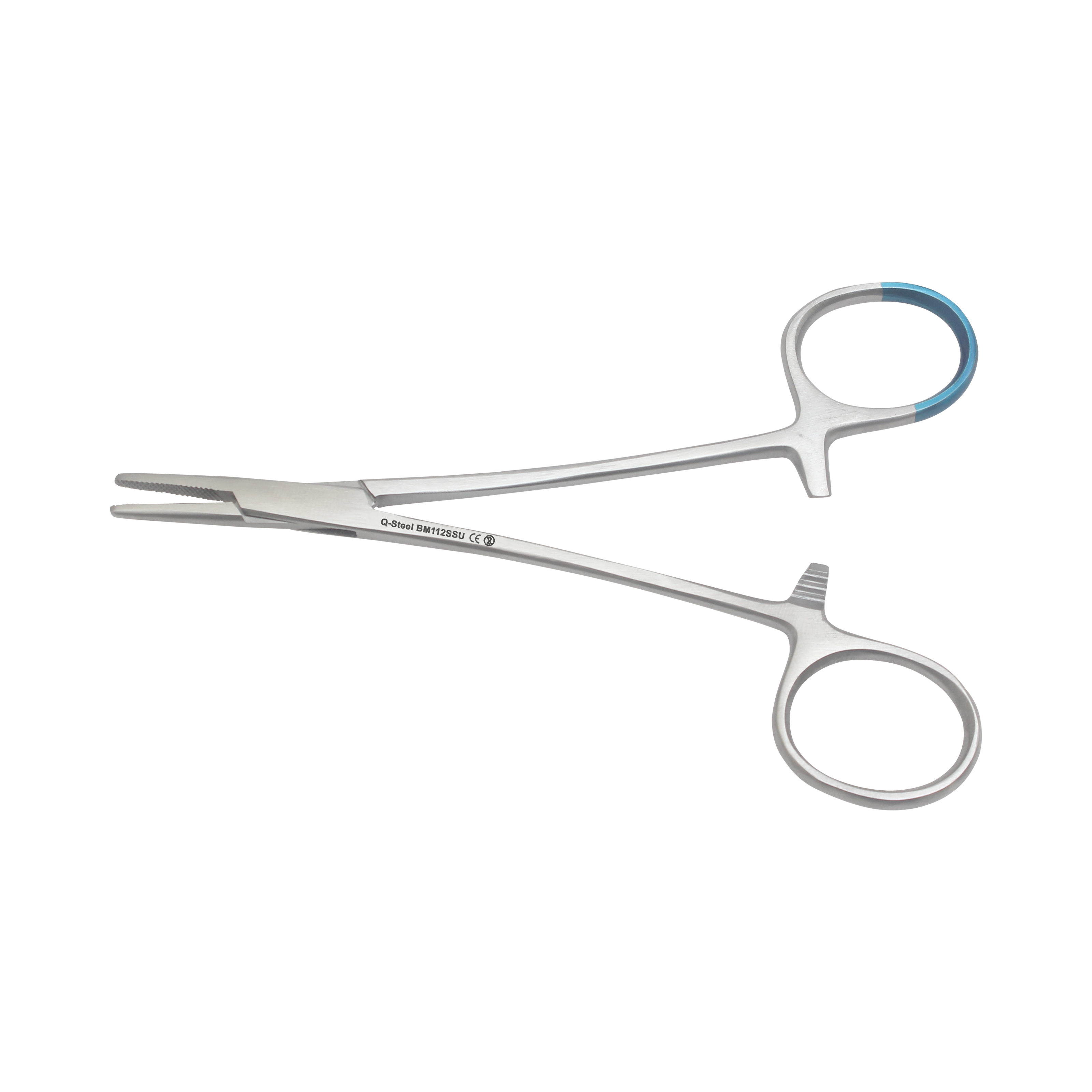

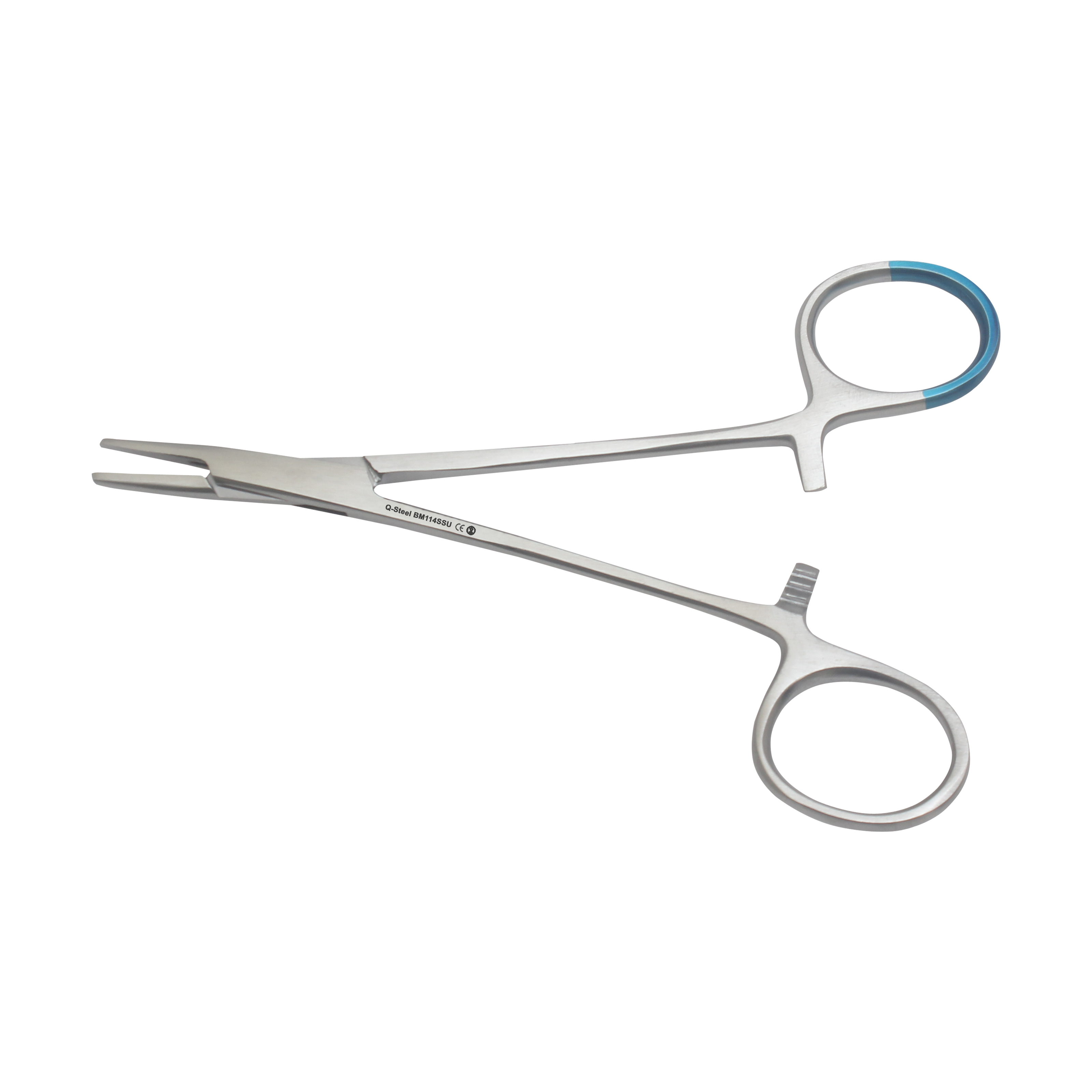

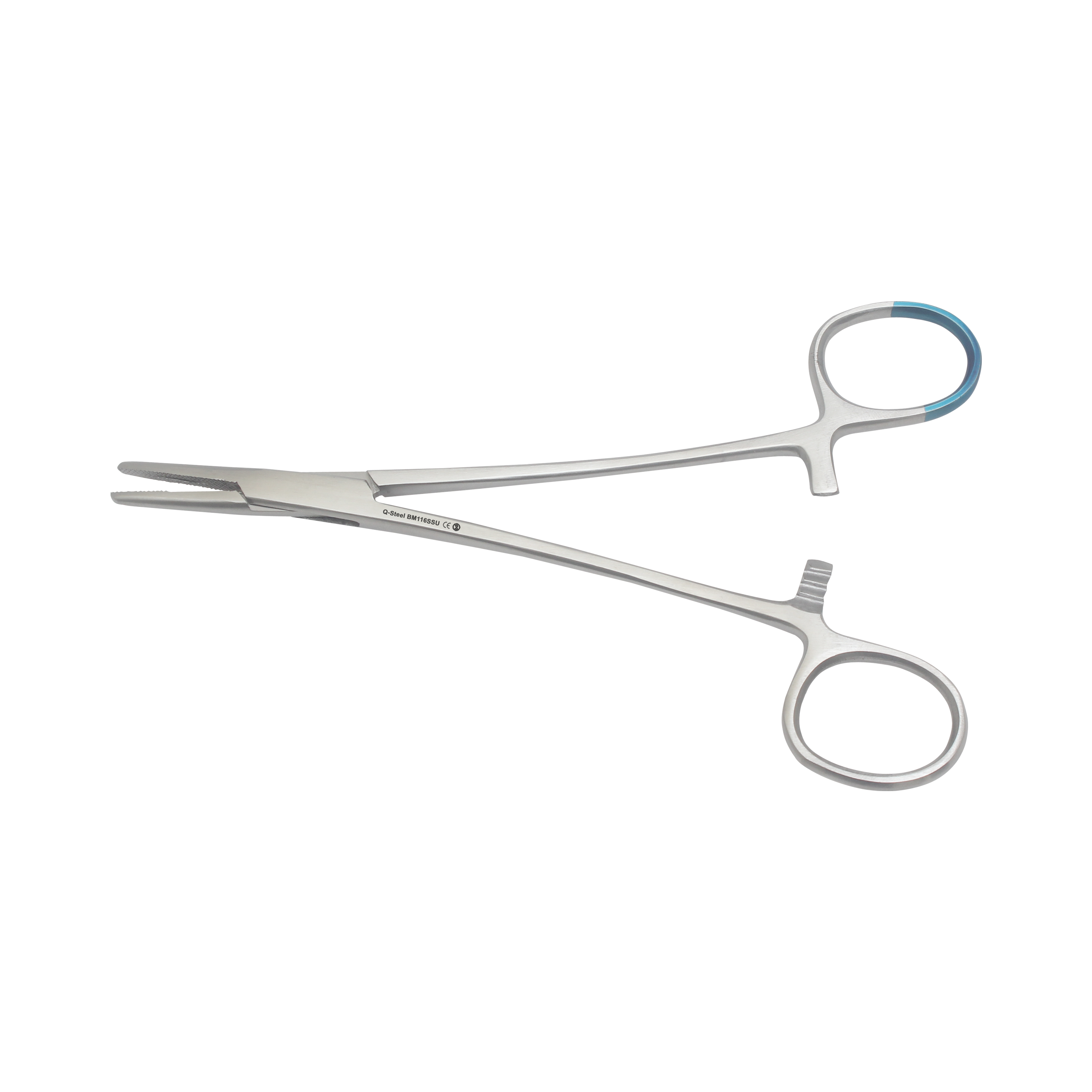

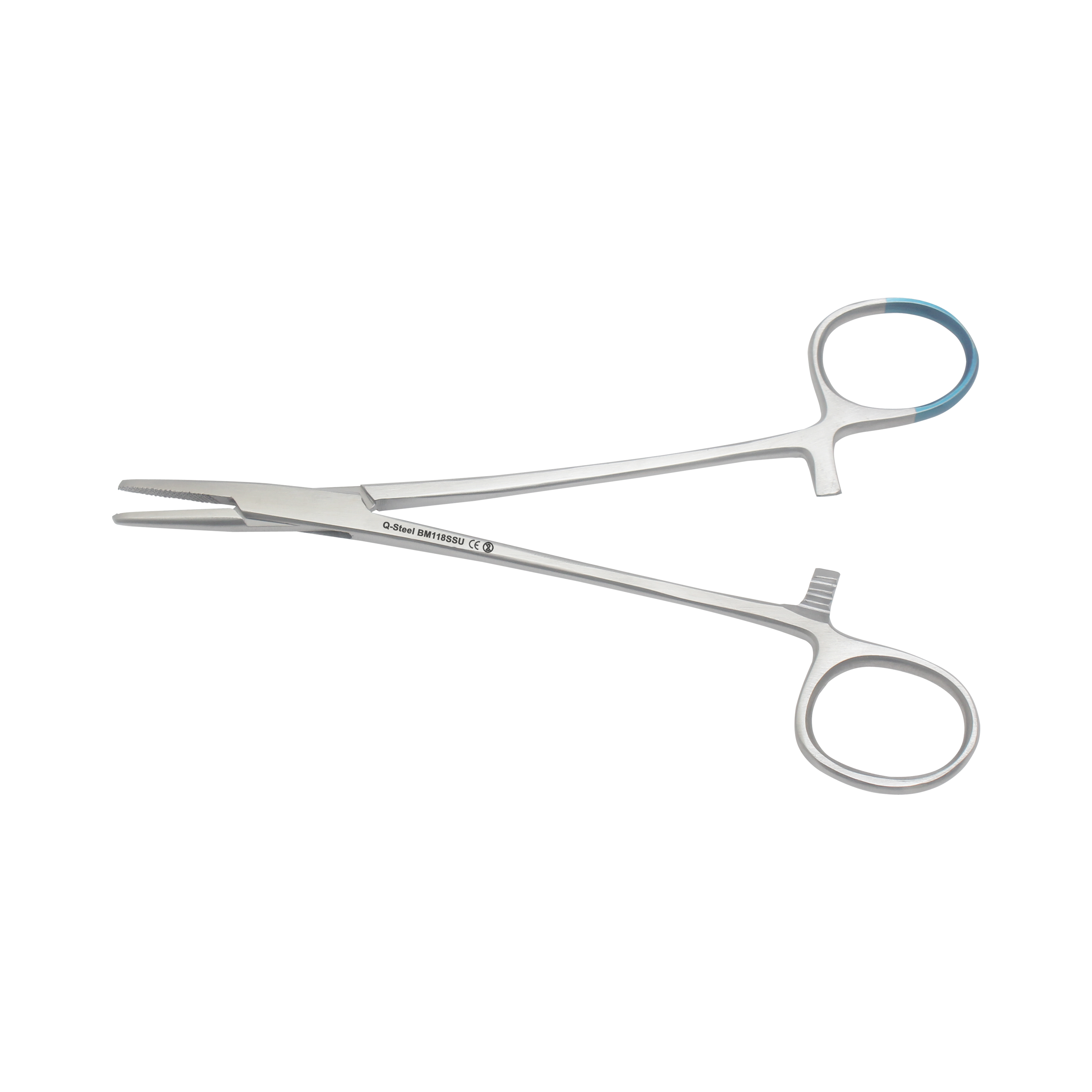

Comparing single use steel surgical instrument with reusable steel surgical instruments, visually – there is very little difference. What is the difference? The steel.

Single use Q-Steel instruments are made of standard carbon steel. And reusable instruments are made of high-quality steel.

Reusable instruments need to be able to withstand, repeated washing, detailed cleaning and sterilization cycles for many years whilst maintaining their mechanical and chemical properties. This steel used has additional alloying elements such as Chromium, Molybdenum, Vanadium, Manganese and Nickel. These elements alter the properties, providing advantages over standard carbon steel. It is essential manufacturing process is of a high quality, using the best raw materials ensuring performance, longevity and endurance over time.

Besides the main difference of steel quality.

Single Use instruments – Most manufacturers, use raw materials, at different lower quality production processes. Some omit manufacturing processes like passivation – a chemical treatment to prevent rust. Skipping some of these processes, using cheaper raw materials is acceptable because in these cases the instruments will only be used once.

Single use Q-Steel instruments are especially manufactured under supervision. Our QA/QC Staff (quality assurance / quality control) are attached to our contract manufacturer – this process ensures products and services meet consumer expectations.

Q-Steel Sterile Single Use Surgical Instruments are of the same quality as reusable instruments, with exception of the steel used (Pakistani carbon steel, which is a lower-cost). Undergo a similar manufacturing process, the same quality inspection criteria as in the reusable line and do not compromise on cheaper quality consumables.